Services

We produce cores for foundries in cast iron, aluminium, bronze, steel and light alloys. We check all stages of the core production process, following its development from the creation of the mould to the qualitative analysis of the finished product.

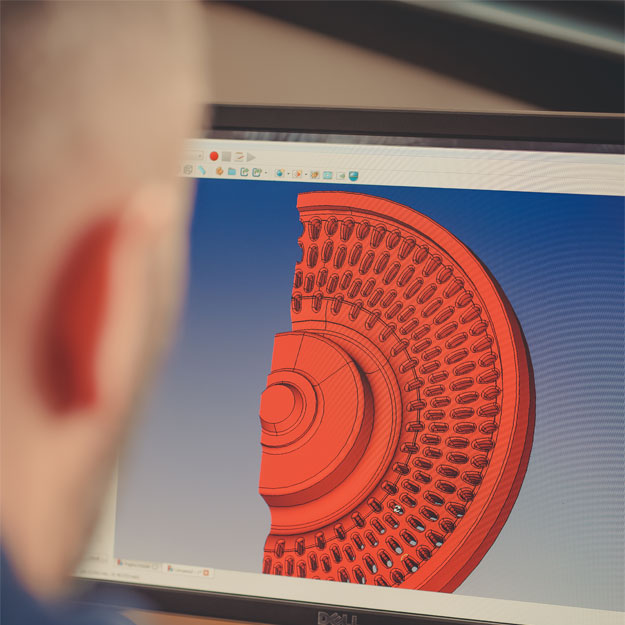

Design

We follow the customer in all the stages of the core manufacture, giving support, through our technical office, in the design and execution of the mould. We are able to analyse the box gemoetries using 3D software and help customers to solve issues, guiding them in the best choices to optimize the production yield.

Requesting use of special blends and additional processes for the core is possible:

- Special sands such as cerabead, chromite or synthetic sands.

- Special additives to improve the casting process and avoid flaw formation

- Application of reinforcements and extraction hooks

- Bonding/assembly of composite parts

- Surface painting

Volume production

The core production cycle takes place over 3 shifts, ensuring high availability and fast turnaround times. We use a software (developed in-house) able to connect to the systems, via which we are able to:

- Plan production on the basis of orders

- Monitor the work progress in real time

- Analyse productivity by highlighting critical issues to optimize processes

The production department is composed as follows:

- Shell moulding department

- Cold box department

- Painting department

Logistics and Shipping

We have 3 trucks for the delivery of the cores.

We also rely on external haulage companies and we are able to deliver cores throughout Italy and abroad.

Maintenance & Quality Control

We have an in-house workshop for the tooling and maintenance of core boxes and a quality control office to constantly monitor the production standard. In 2004, our quality control system obtained UNI EN ISO 9001-20015 certification for the core production process for foundries in accordance with specifications provided by the customer.

Sample analyses are performed on finished products, with measurements of the main technological and geometric parameters:

- Particle size checks

- Acid demand

- Loss on calcination

- Check warping before and after painting

- Tensile strength

- Geometric checks with reference plane and electronic comparators

- Paint thickness check

Sampling

Requesting sampling through a small series to test the quality of the product is possible. Production parameters are tested and, on the basis of the results, all relevant adjustments are made to both the equipment and the machine configuration